How to Use Phoenix Connectors for Efficient Wiring Solutions?

In the realm of electrical wiring solutions, "Phoenix Connectors" stand out for their efficiency and reliability. Leading industry expert, Dr. Emily Zhang, once stated, "Phoenix Connectors transform the way we approach wiring projects." This highlights the pivotal role these connectors play in enhancing connectivity.

Phoenix Connectors offer a blend of versatility and ease of use. Their design allows for quick and secure connections, making them ideal for various applications. Despite their many advantages, some users report challenges during installation. These difficulties can stem from inadequate training or a lack of familiarity with the product. Reflecting on these issues can lead to a more thoughtful approach.

Understanding the nuances of Phoenix Connectors can lead to better outcomes in wiring projects. By embracing both the strengths and weaknesses of these connectors, professionals can optimize their work. Improved knowledge and practice may turn hurdles into opportunities for mastering efficient wiring solutions.

Understanding Phoenix Connectors and Their Applications

Phoenix connectors are widely used in various industries due to their robust design and reliability. Understanding how to use them effectively can enhance your wiring solutions. These connectors facilitate secure connections in electronic systems, providing an efficient method for wiring tasks. They are particularly favored in automation, control systems, and electrical installations.

When selecting Phoenix connectors, consider the specific application. Different types cater to varying needs such as size, number of poles, and current capacity. Ensure compatibility with your wiring requirements. Pay attention to the insulation type and material, as they affect performance. Using incorrect options could lead to overheating or connection failures.

Tips: Test connections under load to ensure stability. Double-check pin configurations to avoid miswiring. Leverage color coding for easier identification during installation. Small details can make a big difference in performance. Keep your workspace organized to reduce errors. Even experienced technicians can make unexpected mistakes. Revisiting the basics can save time and improve results.

Key Benefits of Using Phoenix Connectors for Wiring Solutions

When considering efficient wiring solutions, Phoenix connectors stand out for various reasons. These connectors provide reliable electrical connections across numerous applications. They come in various sizes and types, making them adaptable to different wiring needs. This versatility makes them a favorite among engineers and technicians.

One significant benefit of using Phoenix connectors is their ease of installation. They can reduce the time required for wiring tasks. Users appreciate quick connection options, as they help minimize downtime. The design promotes better organization, which is critical in complex setups. However, some may find it challenging during initial installations. Getting used to specific configurations takes practice.

Another advantage is the enhanced safety these connectors offer. Many designs feature secure locking mechanisms. This reduces the risk of accidental disconnections. Yet, improper handling can lead to issues. Ensuring compatibility with existing systems is crucial. Users need to double-check specifications to avoid costly mistakes.

Step-by-Step Guide to Installing Phoenix Connectors

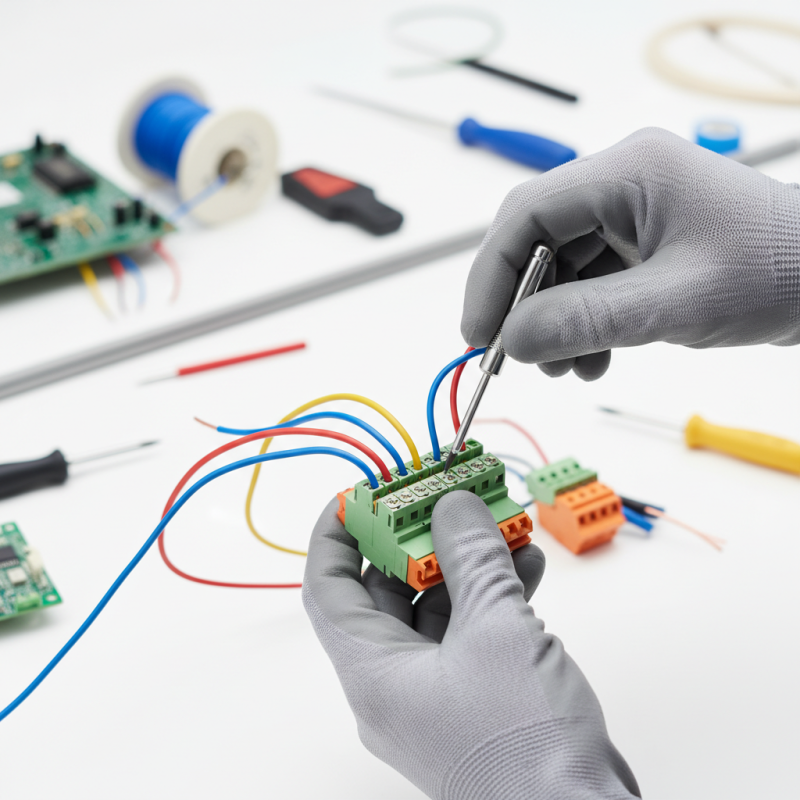

Installing Phoenix connectors can enhance wiring solutions significantly. Begin by gathering all necessary tools and materials. You will need wire strippers, a screwdriver, and the connectors themselves. Ensure you have the right connectors for your application. Measure and cut the wires to the needed length. This step often takes longer than expected.

Next, strip the wire ends carefully. A clean strip is crucial for a solid connection. Insert the stripped wire into the connector, ensuring a snug fit. It's easy to overlook the alignment; double-check before tightening any screws. Sometimes, the connector may not hold as expected. If this happens, don’t hesitate to start over with a new connector.

After securing the wires, verify each connection. This gives you peace of mind about your installation. Mistakes can happen, even for seasoned professionals. Before finishing, take a moment to reflect on your work. Is everything in place? Adjustments might be necessary if you notice any misalignments. Proper installation demands attention to detail, so don’t rush this final check.

Best Practices for Maintaining Phoenix Connectors

Maintaining Phoenix connectors is crucial for ensuring long-term functionality. These connectors are often used in demanding environments. Regular inspections help identify wear and tear early on. Look for damaged insulation or loose connections. A simple visual check goes a long way.

Cleaning is another essential practice. Use a soft brush or cloth to remove dust and debris. Avoid harsh chemicals that can cause damage. Ensure connectors are dry before reconnection. Moisture can lead to corrosion over time, impacting performance.

Proper installation also plays a key role in maintenance. Follow guidelines closely to prevent issues down the road. Oversights during installation can lead to costly repairs. If connections are too tight, it may cause breakage. Check compatibility with wiring to avoid functional failures. By adopting these practices, users can enhance the reliability of their wiring solutions.

Common Challenges and Troubleshooting Tips for Phoenix Connectors

When dealing with wiring solutions, using connectors effectively can be challenging. Common issues include improper connections and cable management. These problems can lead to communication failures and faulty systems. Identifying the root cause requires careful inspection of each connection point. Sometimes, cables may appear secure but are not making proper contact.

Another challenge is keeping connectors organized. A tangle of wires can make troubleshooting difficult. Labeling each wire can help streamline the process. When a problem arises, a clear layout allows for quicker identification. Additionally, using the right tools is essential. If connectors are not crimped correctly, it can lead to intermittent faults that are hard to trace.

In troubleshooting, patience is crucial. Sometimes, taking a step back helps to see the big picture. Don't rush; errors often occur when you're in a hurry. Asking for a second opinion can also lead to new insights. It’s vital to document each step taken during troubleshooting. This practice can reveal patterns and help avoid repeating mistakes.