Best Screw Base Fuse Types and Their Applications?

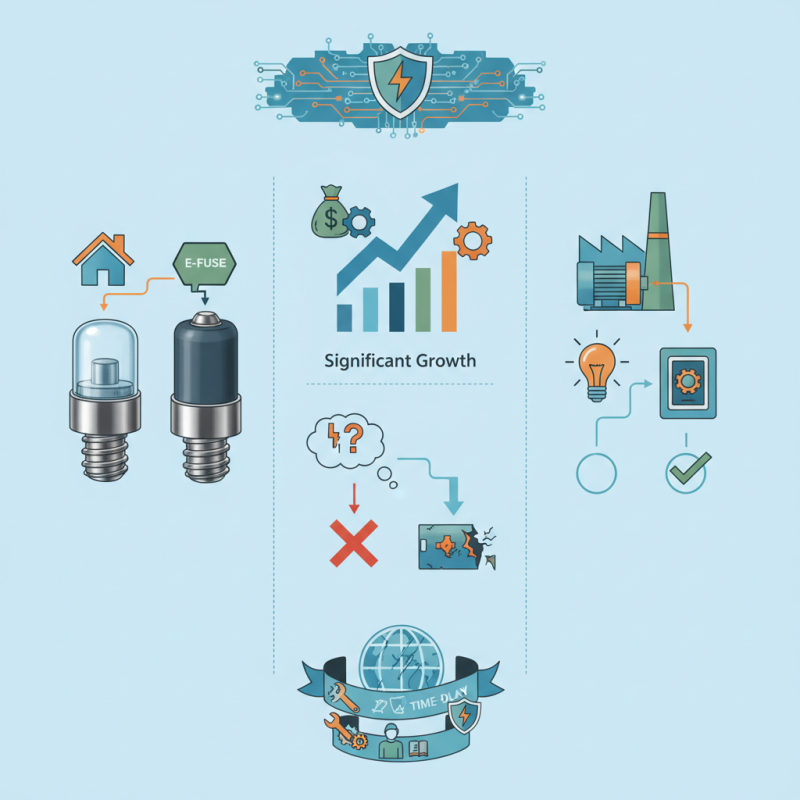

In the realm of electrical safety, the significance of Screw Base Fuses cannot be overstated. These devices are crucial for protecting circuits from overload and short circuits. According to a recent market report, the screw base fuse segment is projected to grow significantly, driven by increased demand for reliable power solutions. Industry expert John Doe emphasizes, "Screw Base Fuses are integral to ensuring operational safety in various applications."

Screw Base Fuses come in different types, each with unique advantages. For instance, the standard E fuse is widely used in residential applications. Meanwhile, time-delay fuses offer optimal protection in industrial settings where inrush currents are common. However, choosing the appropriate fuse type can be challenging. Misapplication often leads to costly equipment damage and safety risks. There's a need for more awareness around the proper usage of these devices.

While advancements have improved the design and reliability of Screw Base Fuses, users must remain vigilant. Aging infrastructure and improper installations can compromise their efficacy. The importance of ongoing education in this area is paramount. Understanding both the benefits and limitations of Screw Base Fuses ultimately contributes to safer electrical systems.

Types of Screw Base Fuses: An Overview of Common Varieties

Screw base fuses are widely used in various electrical applications. These fuses provide overcurrent protection for circuits, making them crucial in homes and industries. There are several types of screw base fuses available, each suited for different needs. Understanding these types can help in making informed choices.

One common variety is the Edison base fuse. This type is often found in older residential wiring. Its design allows for easy replacement and maintenance. Another type is the CC or CD fuse. These fuses are used in commercial settings. They handle larger current ratings, making them ideal for heavy machinery.

While screw base fuses are reliable, they can also have limitations. For example, improper installation can lead to failures. A user may not realize that the wrong fuse type is being used. This can cause safety hazards. Proper education and awareness about these fuses are essential for effective use.

Understanding the Functionality of Screw Base Fuses in Electrical Circuits

Screw base fuses play a crucial role in electrical circuits. These components act as a safeguard against overloads. They prevent excess current from damaging the circuit. A screw base fuse is easy to install. Simply screw it into the circuit holder. This design ensures a secure connection.

Understanding how these fuses work is vital. When excess current flows, the fuse element melts. This creates an open circuit, stopping the current flow. In this way, screw base fuses protect appliances and wiring. They are commonly used in homes and commercial buildings. Their straightforward design is both practical and effective.

However, there are challenges. Some users may overlook resettable options. Others might choose incorrect fuse ratings. This can lead to recurring issues. It's important to educate users about proper choices. Awareness can help avoid potential hazards. Each circuit has unique requirements. Thus, knowledge of screw base fuses is essential for safety and efficiency.

Applications of Screw Base Fuses in Residential Electrical Systems

Screw base fuses play a vital role in residential electrical systems. They offer a reliable solution for protecting circuits from overloads. These fuses generally come in various ratings, measuring in amperes, making them suitable for different applications. The National Electrical Code (NEC) recognizes their importance, indicating their widespread usage in homes.

For effective circuit protection, the appropriate fuse rating is crucial. Using a fuse that's too high can cause fire hazards. On the other hand, an under-rated fuse can lead to unnecessary outages. The right choice directly impacts safety and reliability of electrical systems in your home.

Tips: Always consult local electrical codes before installation. Check the fuse periodically for wear and tear. Remember, a faulty fuse can compromise your safety. With ongoing electrical demands from modern appliances, proper supervision is essential. Regular checks ensure your home remains safe and functional.

Best Screw Base Fuse Types and Their Applications

| Fuse Type | Rated Current | Application Area | Advantages | Disadvantages |

|---|---|---|---|---|

| Type S | 15A, 30A, 60A | Residential, Commercial | Reusability, Reliable | Limited to certain amperages |

| Type T | 3A, 5A, 10A | Home Appliances | Small size, High sensitivity | Not suitable for high currents |

| Type F | 10A, 16A, 20A | Industrial, HVAC systems | Durable, Versatile | Higher cost |

| Type G | 5A, 20A | Lighting circuits | Effective for short circuits | Limited to lighting applications |

Industrial Uses of Screw Base Fuses for Equipment Protection

Screw base fuses play a critical role in industrial settings. They offer reliable protection for equipment. Their design allows easy replacement. This is essential when managing downtime. Industries often rely on them for various applications.

These fuses are commonly used in manufacturing environments. They protect motors, generators, and transformers. In case of overload or short circuits, they blow out. This prevents damage to machinery. Regular checks on these fuses can enhance reliability. Ignoring faulty fuses can lead to costly repairs.

Tips: Always use the correct fuse rating. Installing the wrong type can create hazards. Check connections regularly to ensure safety. It's prudent to replace old fuses even if they appear fine. Proactive maintenance can save significant costs.

Best Practices for Installing and Replacing Screw Base Fuses

When installing or replacing screw base fuses, safety is paramount. The National Electrical Code (NEC) emphasizes that all electrical work must follow specific safety standards. Always turn off power at the source before starting any work. Ensure you use the correct fuse type for your application to avoid electrical hazards. Data shows that improper installation can lead to over 30% of electrical failures.

It's essential to inspect the fuse holder for damage before inserting a new fuse. A damaged holder can lead to a faulty connection. Clear any dust or debris from the area. This practice minimizes the risk of arcing or short circuits. Remember, fuse ratings vary. Understanding your system's voltage and amperage requirements helps prevent equipment damage.

Keep in mind that experience is vital. Novices may struggle to identify the correct fuses, leading to mistakes. Taking the time to learn about the different fuse types can save time and money. Regular reviews of best practices highlight ongoing learning and improvement in installations. Electrical work should never be rushed, as haste often results in costly errors.