What is an Offset Inline Inspection System and How Does It Work?

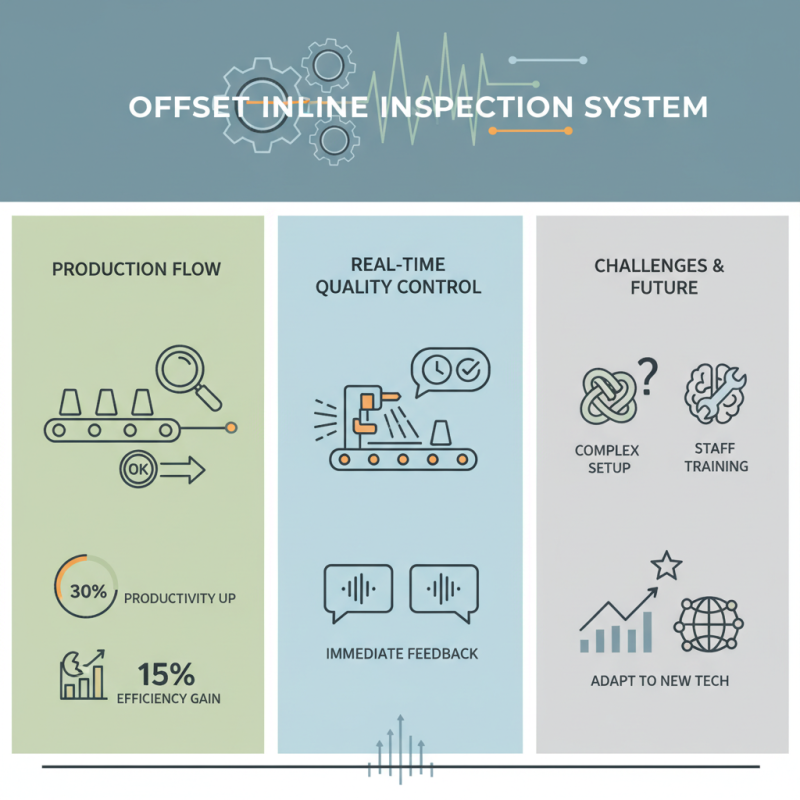

The Offset Inline Inspection System plays a crucial role in the manufacturing industry. This innovative technology enables real-time inspection during production. According to a recent report by Advanced Manufacturing Insight, up to 30% of defects in products can be detected with such systems. Industry expert Dr. Emily Chen noted, "The Offset Inline Inspection System revolutionizes quality control by providing immediate feedback on production quality."

Implementing this system has practical benefits. It reduces waste and increases productivity. Companies using offset systems report a 15% improvement in overall efficiency. However, challenges remain. The initial setup can be complex. Training staff on these systems requires time and resources. It is essential to address these hurdles to maximize the benefits.

Data shows that businesses not utilizing Offset Inline Inspection Systems may be falling behind. The lack of real-time feedback can lead to higher defect rates. Dr. Chen emphasizes the importance of adapting to new technologies. "Embracing innovation is crucial for staying competitive in a fast-paced market," she states.

Definition of Offset Inline Inspection Systems

Offset Inline Inspection Systems are essential in modern manufacturing. They ensure quality control throughout production processes. These systems use advanced technology to monitor and check products as they move along the production line. This minimizes waste and increases efficiency.

The term "offset" refers to how these systems are positioned relative to the production line. They are usually aligned parallel to the flow of materials. This design allows for quick inspections without stopping the production. The inspection can identify defects or inconsistencies in real-time. For instance, sensors detect flaws in packaging or measurements.

Still, challenges exist. Environmental factors can affect performance. Variations in material may lead to incorrect readings. Regular calibration and adjustments are necessary. Operators must stay vigilant. They should ensure that the system functions accurately. Continuous improvement in processes is crucial for optimal results.

Components of an Offset Inline Inspection System

An Offset Inline Inspection System is essential in modern manufacturing. Its components play a vital role in ensuring product quality. The primary elements include cameras, sensors, and software. Each part works together to detect defects and inconsistencies.

Cameras capture images of the products as they move along the production line. They provide real-time visual feedback. Sensors complement the cameras by measuring dimensions and checking for weight inconsistencies. Together, they create a comprehensive picture of product quality.

The software is where the magic happens. It analyzes the data gathered from cameras and sensors. However, it is not infallible. Occasionally, the system may miss subtle defects. This highlights the need for human oversight. Continuous improvements are crucial to enhance accuracy. More frequently, manufacturers are reflecting on how to optimize the system’s performance.

How Offset Inline Inspection Systems Operate

Offset Inline Inspection Systems play a crucial role in maintaining quality during manufacturing processes. These systems leverage advanced sensors and imaging technology to inspect products in real-time. A recent market report indicates that the global demand for inline inspection systems is projected to reach $5 billion by 2026. This growth reflects the increasing emphasis on quality assurance across various industries.

These systems operate by utilizing high-speed cameras and optical sensors to capture images of the products as they move along the production line. The data is analyzed instantly, allowing immediate feedback for quality control. Studies show that constant monitoring can reduce defects by up to 40%. This level of efficiency is essential, considering that defects can lead to significant financial losses and customer dissatisfaction.

However, challenges exist. Implementing these systems requires substantial investment. Additionally, not all inspection systems can catch every type of defect, leading to potential oversights. Reports suggest that around 20% of manufacturers still rely on manual inspection. This highlights an area for improvement in embracing technology. As manufacturing complexity increases, so does the need for reliable inspection methods.

Applications of Offset Inline Inspection Systems in Industry

Offset Inline Inspection Systems play a crucial role in various industries, enhancing quality control and operational efficiency. These systems are commonly used in manufacturing, particularly in sectors like automotive and food processing. According to a recent report by Industry Insights, manufacturers that employ inline inspection technologies can reduce defects by up to 40%. This leads to fewer recalls and increased customer satisfaction.

Tips: Regular training on system operation is essential. Ensure staff understands how to interpret inspection data effectively.

Moreover, the application of Offset Inline Inspection Systems extends to packaging. These systems can ensure that packaging meets industry standards, which is vital for consumer safety. Data from the Packaging Association reveals that 30% of product recalls are due to packaging errors. Hence, an effective inspection system can mitigate these risks significantly.

Tips: Invest in software that provides real-time analytics. Quick insights can improve decision-making processes.

In the printing industry, these systems help in maintaining consistency in colors and quality. Variability can lead to significant losses, both financially and in brand reputation. However, the implementation of these systems sometimes faces resistance. Employees may be hesitant to adapt to new technologies. It's essential to address these challenges through comprehensive change management strategies.

What is an Offset Inline Inspection System and How Does It Work? - Applications of Offset Inline Inspection Systems in Industry

| Application Area | Technology Used | Benefits | Challenges |

|---|---|---|---|

| Food Packaging | Vision Systems, X-ray Technology | Increased efficiency, Quality assurance | High initial setup cost |

| Pharmaceuticals | Optical Sensors, Laser Scanning | Regulatory compliance, Serialization | Complex integration with existing systems |

| Automotive Manufacturing | Ultrasonic Testing, Magnetic Particle Inspection | Enhanced safety, Operational reliability | Skilled operator requirement |

| Electronics | Automated Optical Inspection (AOI) | Minimized defects, Cost reduction | False positives in detection |

| Textiles | Color Detection Sensors, Texture Analyzers | Consistent quality, Waste reduction | Difficulty in handling various materials |

Advantages and Limitations of Offset Inline Inspection Systems

Offset inline inspection systems offer various advantages in industrial applications. They enhance production quality. These systems enable real-time monitoring during the manufacturing process. This leads to immediate identification of defects. Immediate feedback helps in reducing waste. Additionally, the integration into existing workflows can be seamless. Operators receive alerts for any potential issues. This allows for timely interventions.

However, there are limitations to consider. Offset systems may require significant upfront investment. Not every operation may justify the cost. Moreover, some materials may not be compatible with these systems. This can limit their application in diverse environments. Additionally, operators must be adequately trained. Misinterpretation of data could lead to improper actions. Regular maintenance is crucial for consistent performance. Failure to maintain the system can result in inaccurate readings. This poses risks to the overall quality control process.