What is a High Speed Inspection Machine and How Does It Work?

The High Speed Inspection Machine is a pivotal tool in various industries. It ensures quality and efficiency in production lines. These machines quickly assess products, identifying defects that human eyes might miss.

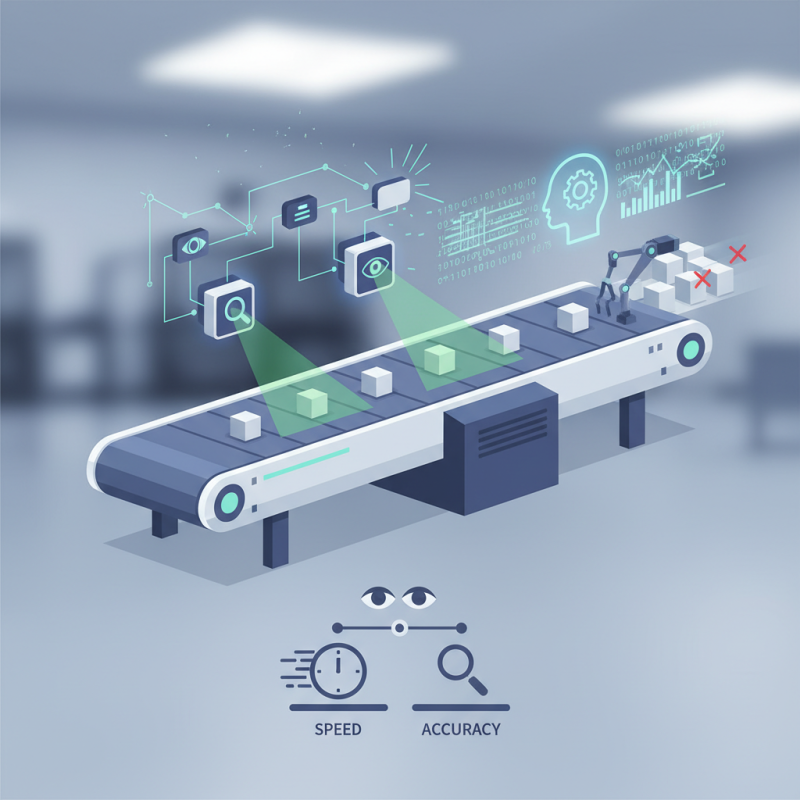

Equipped with advanced sensors and cameras, the High Speed Inspection Machine operates at remarkable speeds. It captures images and analyzes data in real-time. This process helps maintain product standards and boosts overall productivity.

However, reliance on this technology raises questions. Can it miss subtle defects? Are machines always accurate? These concerns remind us that while technology advances, human oversight remains vital. Balancing speed and accuracy is essential in ensuring quality control.

Definition and Purpose of High Speed Inspection Machines

High-speed inspection machines are essential in various industries, such as food packaging and pharmaceuticals. They ensure that products meet safety and quality standards. According to a recent industry report, the global market for inspection machines is projected to reach $14.5 billion by 2027, growing at a compound annual growth rate of 6.4%. This growth highlights the increasing reliance on automation for quality assurance.

These machines operate using advanced imaging technology. High-speed cameras capture images of each product as it moves along the production line. The machines analyze these images for defects or inconsistencies. Reports indicate that these systems can inspect up to 600 items per minute, which significantly enhances productivity. However, they are not infallible. False positives can occur, leading to unnecessary product rejections and waste.

Despite their efficiency, high-speed inspection systems require regular calibration and maintenance. A poorly maintained machine can cause delays and quality issues. Additionally, staff must be trained to operate and troubleshoot these systems effectively. There is an ongoing need for improvement in integration with existing production lines. Balancing speed and accuracy remains a challenge that many manufacturers face in this evolving landscape.

What is a High Speed Inspection Machine and How Does It Work?

| Dimension | Description | Example Values |

|---|---|---|

| Inspection Speed | The rate at which the machine inspects products. | Up to 600 products/min |

| Camera Resolution | The clarity and detail of the images captured for inspection. | 5 MP to 20 MP |

| Detection Accuracy | The ability of the machine to correctly identify defects. | 99.9% accuracy |

| Types of Defects Detected | Common flaws that the machine can identify during inspection. | Scratches, dents, color inconsistencies |

| Integration Capability | How well the machine can be incorporated into existing production lines. | Seamless integration with conveyors |

| Operator Training Required | The level of training needed for staff to operate the machine. | Basic to Advanced training sessions |

Key Components of High Speed Inspection Machines

High-speed inspection machines are essential in various industries, ensuring product quality and efficiency. These machines typically consist of several key components. The camera system captures high-resolution images of products as they move on a conveyor. Advanced image processing algorithms analyze these images in real time. This allows for immediate feedback on product quality.

Another critical component is the lighting system. Proper lighting enhances image clarity, allowing for accurate detection of defects. Reports indicate that as much as 90% of inspection accuracy depends on optimal lighting conditions. Moreover, the conveyor system needs to be aligned with the inspection speed. If not, it can cause bottlenecks, reducing overall throughput.

Tips: Always calibrate the camera system regularly. This ensures consistent performance and reliable results. Regular maintenance on the lighting is also crucial. Dimming or flickering can severely impact inspection quality. Additionally, invest time in training operators. They should understand both the technology and the inspection metrics. An informed operator can adjust the machine settings for varying product runs, enhancing efficiency and accuracy.

Principles of Operation for High Speed Inspection Technology

High-speed inspection machines play a crucial role in quality control. They rapidly assess products in various industries. These machines use advanced technologies to detect defects and anomalies. They can identify issues even at high speeds. This ensures that only the best products reach consumers.

The principles of operation are fascinating. Most high-speed inspection systems use cameras or sensors. These devices capture images or data of each product. The system then analyzes this data in real-time. Algorithms quickly process the information. This allows operators to make immediate decisions. However, the technology is not without flaws. Calibration issues can lead to erroneous results. Sometimes, a good product may be incorrectly flagged.

Additionally, environmental factors can affect performance. Dust and lighting changes might interfere with inspection accuracy. Maintaining these machines requires constant attention. Regular maintenance helps reduce these risks. Still, not all users prioritize this aspect. Many overlook the importance of routine checks. This can lead to increased defects slipping through unnoticed.

Applications of High Speed Inspection Machines in Various Industries

High-speed inspection machines are transforming various industries. These devices quickly assess product quality. They can identify defects, label errors, or packaging mistakes in real-time. This rapid analysis ensures that only the best products reach consumers. In the food industry, for example, they check for contamination or improper labeling. Accuracy is key, but these machines often struggle with unusual shapes or sizes.

In pharmaceuticals, high-speed inspection machines play a vital role. They verify the integrity of packaging and ensure dosage accuracy. Mistakes here can lead to serious health risks. Yet, some machines may miss minute flaws. Regular calibration and updates are necessary to maintain reliability.

The electronics sector also benefits from these machines. They detect soldering defects or misaligned components on circuit boards. High-speed inspection machines save time and reduce costs. However, they cannot replace human intuition and judgment entirely. Each industry must find the right balance between technology and human oversight.

Benefits and Challenges of Implementing High Speed Inspection Systems

Implementing high-speed inspection systems in manufacturing brings significant benefits. These systems enhance product quality by detecting defects quickly. They can increase production rates without sacrificing accuracy. For instance, a fast-paced production line can maintain efficiency while ensuring consistent quality. This is crucial in industries where precision matters, like food and pharmaceuticals.

However, challenges accompany these advantages. High-speed systems require substantial initial investments. The technology needed can be costly. Training staff to operate these machines effectively adds to expenses. Furthermore, maintenance can be complex. If issues arise, resolving them takes time and effort. Companies must weigh the advantages against these hurdles carefully. Balancing technology and workforce readiness can be tricky.

Over-reliance on automated systems may lead to complacency among staff. Human oversight is still essential. Employees must remain vigilant, ready to spot issues that machines might miss. Regular inspections and feedback loops should be part of the process. Continuous improvement is needed to ensure systems remain effective and reliable. Balancing automation with human expertise is a continual challenge.